More than hundred years in this business

The town of Debrecen has early become the regional centre of the railways crossing North-East of Hungary: it was back in the middle of the XIXth century, when Tiszavidéki Vasúttársaság (one of those early railway operators) laid the first tracks in Hajdu county in 1857. The network expanded rapidly, so did Debrecen after MÁV (the Hungarian Railways Co., still the only rail operator in Hungary) acquired all the small private operators in 1890. This year MÁV also named Debrecen as its first headquarters in the region.

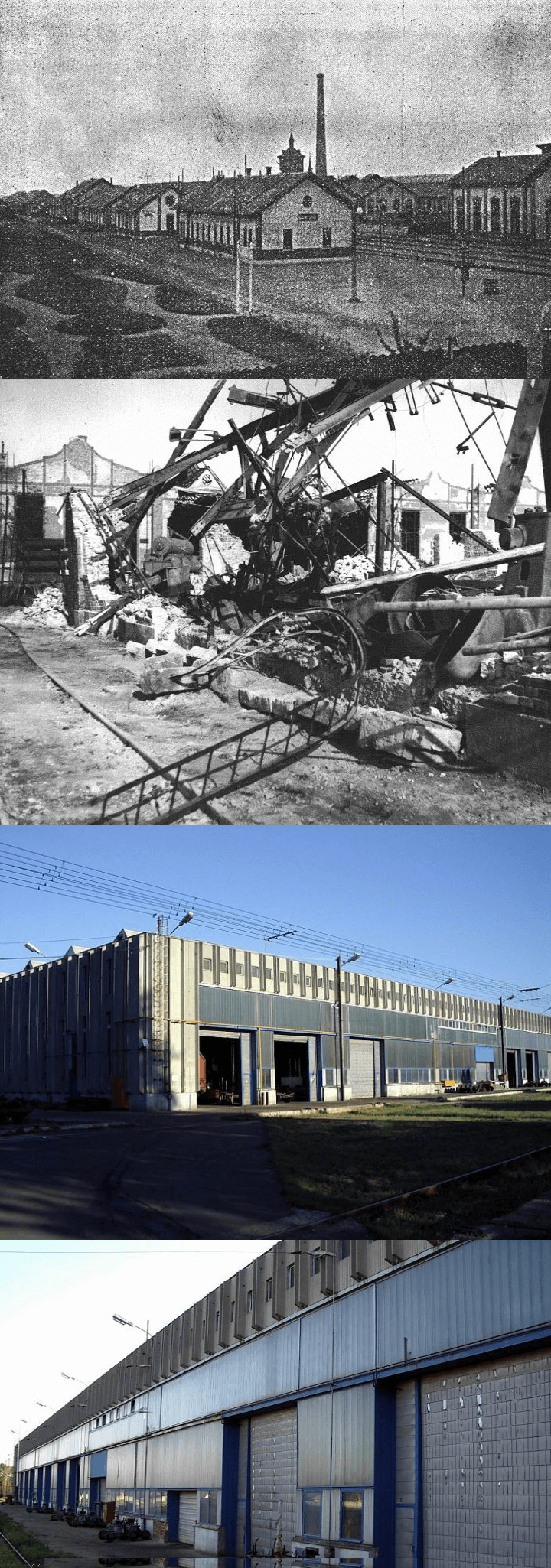

The Railways Service Shop was founded in 1893 in the town. The operations has started on September 20th, 1898 with 264 employees and that time the plant was one f the major employers in the town.

At the beginning Debrecen Shop worked as a master plant and was authorized to offer not only the repair and maintenance, but also the overhaul required for the steam engines, the rail cargo and passenger cars. Next to 58 steam engines, they repaired more than five thousand railcars in the first full year of operation.

The plant recruited its workers from other shops for the start-up, but soon they started up training facilities to accomodate in-house professional education. In 1900 the training shop was set up, where young people were offered of four-years education specialized in all kind of jobs related to the operation.

The master plant was in charge of managing the activities for all the sister plants and thanks to the strong technical standards and commitment, the shop was recognized for quality and timeliness from the early days.

In 1911 the company employed almost thousand people and the owners decided on the first major step in development where the car assembly, the foundry and the carpenter's shop has been expanded. The operation has rapidly grown during the first world war, when the shop started to produce various military items, next to the highly loaded steam engine and railcar repair and maintenance. The plant was the third largest shop in Hungary in 1917 with its 1.553 employees. This size of activities definitely shrunk after the world war, so the output has reached the level of 1914 only thirty years later.

On June 2nd, 1944 a major bombing attack destroyed most of the buildings and machinery.

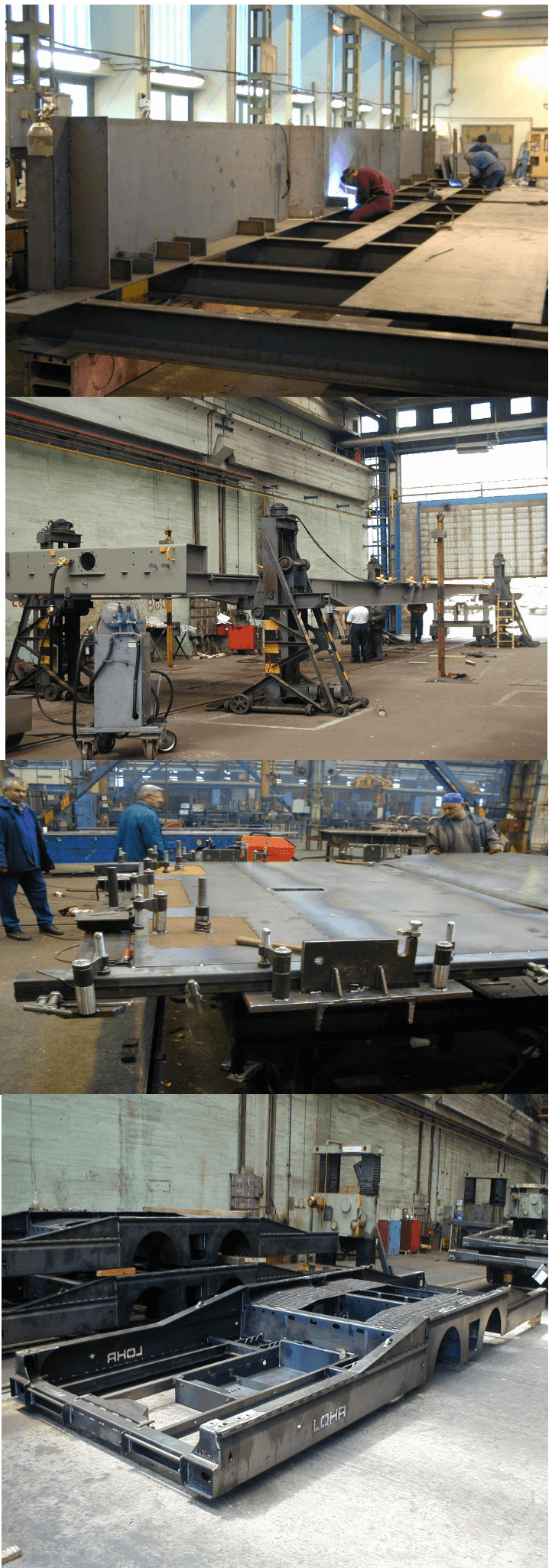

The operation has been restored in 1946 and the shop then focused on its core activities. From 1949 the plant became one of the most influential industrial shops in the region due to its history, size and tradition. During the 1950's the plant steadily increased the output in the repair and maintenance, but also started to build new cargo and passenger cars. Another deal of the period was the conversion of passenger cars with wooden understructure to those built on steel understructure. During the 1960's the country kicked off a large project for transport modernization, so the shops involved in railways maintenance were preferred, too. The plant improved or replaced its machinery, utility supply system and internal material flow and a new paint shop was installed.

Next to the railcars, the company started to build also streetcars this time, when the headcount grown to 2.600. From 1968 the plant became the excellence center for maintenance of tankers and cargo railcars, but manufacturing of new cars has completely disappeared. The only development was made in wheels repair, but the maintenance of steam engines has been shut down by the end of 1970's.

In the 1980's the production volume has significantly increased. This was the time when the new and modern production hall was set-up equipped with utility systems and up-to-date painting facilities.

The quality has definitely improved when the plant invested in cleaning facilities.

These systems are capable of cleaning railcars both inside and outside and were designed and engineered by the process engineers in the plant. For the sake of environmental control, waste water treatment has also been introduced.

The company provided maintenance services for the operators of tankers from the early 1980's, next to the work required by the Hungarian Railways Co.

At the end of 1992 the plant was transformed to an independent legal entity, but 100% of the shares are still in the hands of the Hungarian Railways.

During the last 12 years the company enlarged its customer base and became a long-term partner for railways operators.

In order to improve and secure customer satisfaction, we introduced ISO Quality Assurance System among the first in Hungary, which helped us to become to earn authorisation for all the major railways in Europe.

The new shareholder of our company is the Grampet S.A.